CHANGING HABITS

USING SEAWATER-BASED FRACTURING FLUIDS ONSHORE

Could this be the answer to water sourcing in a drought-prone time?

BY BRENT SMITH, SEAWATER TECHNOLOGIES

From Shale Play Water Management Magazine January/February Issue

USING SEAWATER-BASED FRACTURING FLUIDS ONSHORE

Could this be the answer to water sourcing in a drought-prone time?

BY BRENT SMITH, SEAWATER TECHNOLOGIES

From Shale Play Water Management Magazine January/February Issue

|

(For Personal Use Only)

|

|

INTRODUCTION

We call Earth the Blue Planet. Water covers about 71 percent of its surface. More than 96 percent of that blue water is seawater—one of the most abundant natural resources on Earth’s surface and also one of the oldest. In fact, scientists believe that as much as 40 percent of our water is older than our solar system. Seawater has been here since the beginning of history, albeit a bit saltier than it is today. It is one of the critical ingredients for life itself. Because of seawater’s immense supply, it is logical for mankind to tap into this bounty, especially for preserving fresh water for a huge and growing human population. Seawater Technologies is striving to change the oil and gas industry’s habit of 60-plus years—using fresh water for onshore frac jobs. Looking back over the past 12 years of fracturing history, we clearly see the step-rate change in job size (slurry volume) due to the marriage of horizontal drilling and multistage fracturing. Techniques learned from successful shale fracturing were quickly adopted by operators developing unconventional reservoirs. Multistage horizontal fracturing has proven to be highly effective at making non-commercial, very low permeability reservoirs into economic successes. In turn, that success created an insatiable appetite for fresh water and a whole series of logistical challenges from both the water-supply side and produced-water disposal and/or reuse. Seawater Technologies’ solution to the supply side is seawater. With current freshwater availability and regulation, an oil price-driven slowdown in the frac market, reuse advancements and the development of brackish-water resources, seawater usage on the U.S. mainland may be ahead of its time. However, the opportunities for using the resource as a base fluid for hydraulic fracturing outside of the U.S. are immediate and almost as unlimited as the supply of seawater itself. We have no doubt that seawater will have a long-term supply role in the Lower 48 in years to come. It is not a matter of if, it is a matter of when. |

WATER TYPES AND AVAILABILITY

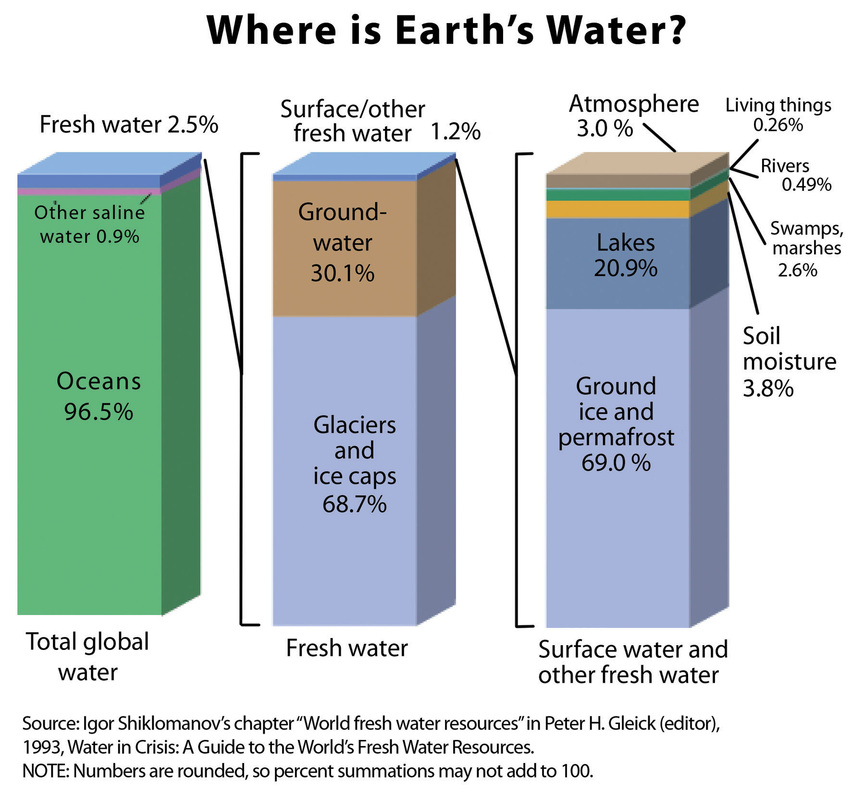

Let’s examine why we are talking about using seawater for fracturing instead of fresh water. Less than 1 percent of all the water on Earth is fresh water in liquid form that is readily usable by man. Most of it is frozen and trapped in the polar icecaps.

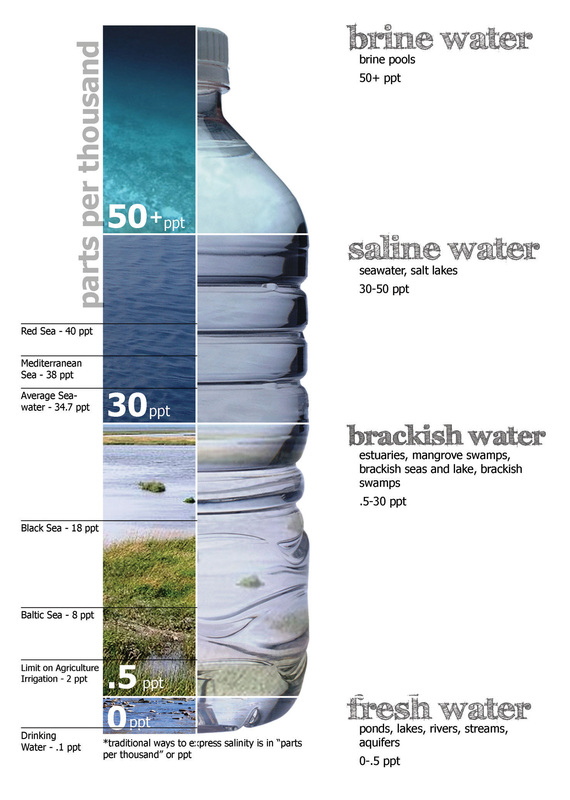

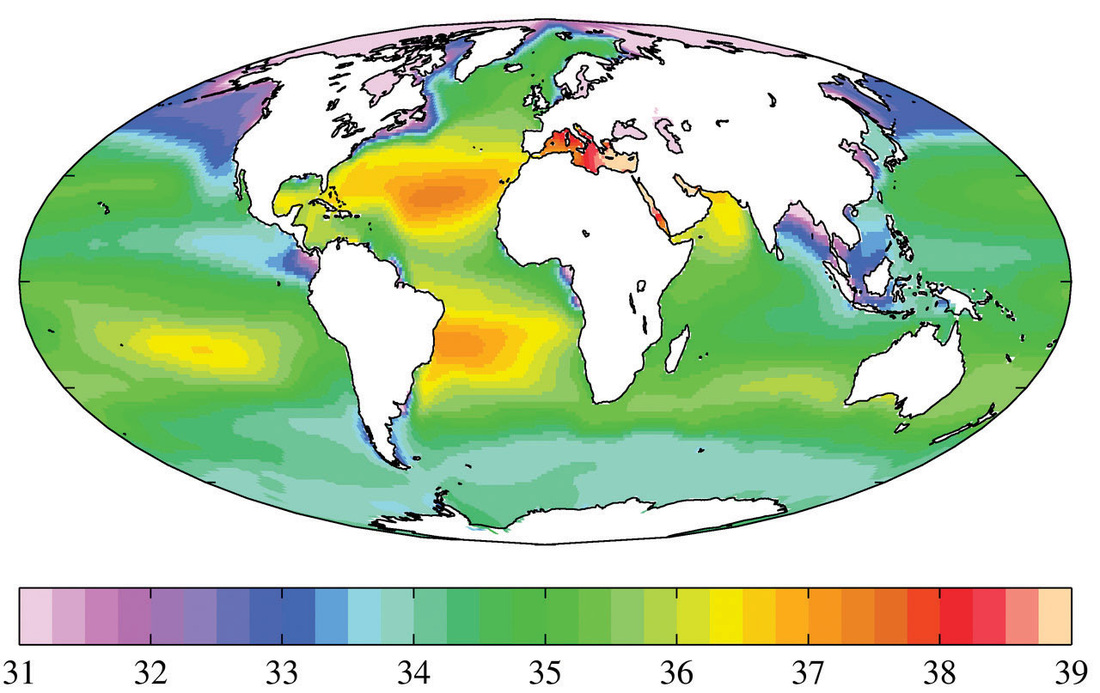

There is approximately the same amount of liquid brackish water on earth as there is liquid fresh water (~1percent of the total amount, each). Brackish water is naturally occurring saltwater, normally groundwater found below freshwater aquifers, ranging in salinity from just slightly salty fresh water to nearly seawater, as seen in Figure 2. Seawater is more than 95 times as abundant as either fresh or brackish water.

At the continental level, North and South America have the largest share of the world’s total freshwater resources with 45 percent, followed by Asia with 28 percent,

Let’s examine why we are talking about using seawater for fracturing instead of fresh water. Less than 1 percent of all the water on Earth is fresh water in liquid form that is readily usable by man. Most of it is frozen and trapped in the polar icecaps.

There is approximately the same amount of liquid brackish water on earth as there is liquid fresh water (~1percent of the total amount, each). Brackish water is naturally occurring saltwater, normally groundwater found below freshwater aquifers, ranging in salinity from just slightly salty fresh water to nearly seawater, as seen in Figure 2. Seawater is more than 95 times as abundant as either fresh or brackish water.

At the continental level, North and South America have the largest share of the world’s total freshwater resources with 45 percent, followed by Asia with 28 percent,

|

Europe 15.5 and Africa 9. The countries with the most liquid freshwater volumes are Brazil, Russia, Canada, Indonesia, China, Columbia, the U.S.’s Lower 48, Peru and India. Changing to a per-capita basis, the 10 poorest countries in terms of water resources are Bahrain, Jordan, Kuwait, Libya, Maldives, Malta, Qatar, Saudi Arabia, United Arab Emirates and Yemen.

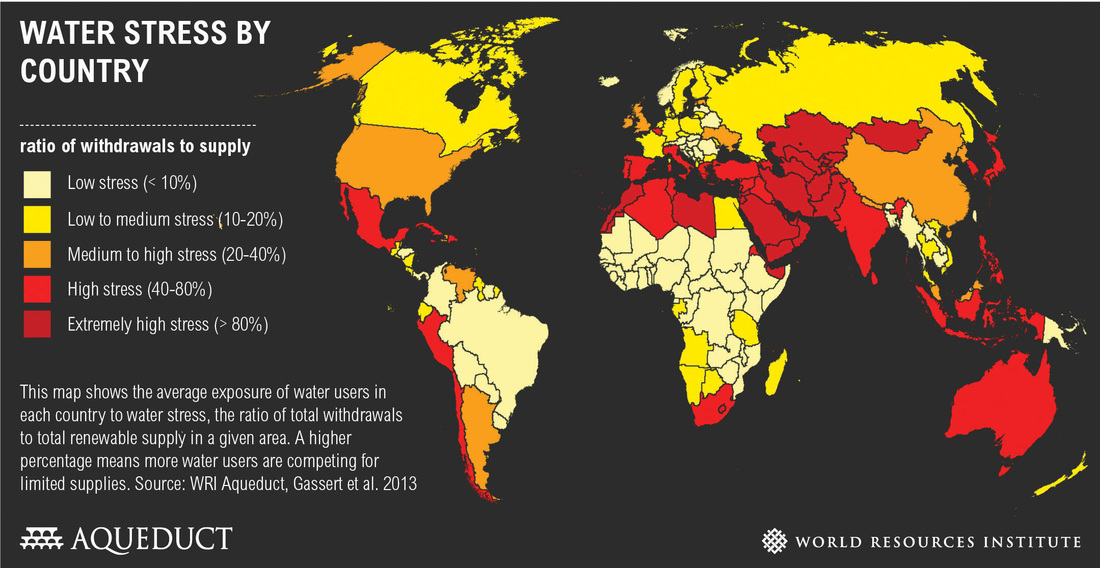

THE GLOBAL SHORTAGE OF FRESH WATER Therein lies the dilemma. Just because there is a big supply in a given country, or region, does not mean that there isn’t a shortage. For example, the U.S. has a huge supply, but also a huge demand for fresh water. In fact, the southwest part of the country is in what scientists call a “mega-drought,” one lasting many years, if not decades. That exacerbates the situation. One-third of the world’s population lives in water-stressed areas, defined in terms of a region’s ratio of water consumption to water availability (including many states in the U.S.). |

Countries labeled as moderate to high stress consume 20 percent more water than their available supply. Even though the oil and gas industry represents a very small percentage of the overall demand on freshwater supplies, it, nevertheless, contributes to the shortage of fresh water in the name of production, which traditionally, does not have a good standing in the media.

Anything that can be done to replace some of the freshwater demands for fracturing, and re-use what is returned to surface, will need to be done. However, there will always be a requirement for new, makeup waters, especially in the countries and regions just beginning to develop their shales and unconventionals, or in areas that produce relatively low amounts of produced water. A recent report by World Resources Institute (WRI) sees every continent other than Antarctica as being water stressed to the point of delaying vital shale and unconventional resource development. For the sake of simplicity, we will lump all unconventional oil-and-gas reserves together and compare those reserves with the availability of fresh water for drilling and fracturing. Countries that will be directly affected by medium to high water stress are the United Kingdom, India, China, Turkey, Paraguay, Canada, South Africa, Pakistan, Argentina, Mexico, the U.S., Saudi Arabia, Algeria, Poland, Ukraine, France and Mongolia. The billions of barrels of fresh water required for industrialized fracturing is simply not available. Aggravating the problem is the fact that in just 11 years, most estimates forecast the world’s population to be eight billion with significant increases in water-stressed regions of Asia. |

|

THE PROPERTIES OF SEAWATER

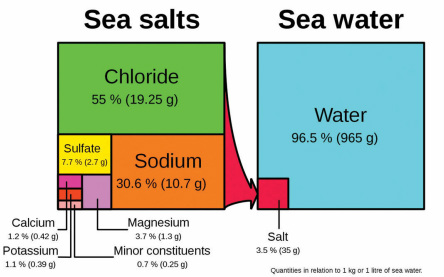

Seawater’s chemical consistency is almost as impressive as its supply. On average, seawater has a salinity of about 3.5 percent (35 g/L, or 599 mM). This means that every kilogram (roughly one liter by volume) of seawater has approximately 35 grams (1.2 oz.) of dissolved salts (predominantly sodium [Na+] and chloride (Cl−) ions). Lack of movement and extreme evaporation in isolated pockets of oceans, such as the Mediterranean Sea, Red Sea, and Persian Gulf (aka Arabian Gulf) cause an elevation in salinity. Overall, what we see is consistent and predictable chemical content on a regional basis. Seawater tends to have very consistent alkalinity with an average pH of about 7.9 (+/- 0.2). The chemical composition in Figure 5 shows the predominant chemicals that we find in seawater. The largest is chloride followed by sodium, sulfate, magnesium, calcium, potassium and other minor constituents.

|

THE SOLUTION—SEAWATER AS A BASE FLUID

FOR ONSHORE FRACTURING Since its experimental debut in 1947, and continuing over the past six decades, fracturing fluids and their chemistry have stayed in stride with the industry’s evolution and changing frac theories. Even today, we see the combination of linear or slickwater fluids being used in combination with complex or cross-linked fluids. Seawater has been used as a base fluid for fracturing offshore wells for several decades. More than 100,000 offshore fracturing treatments used seawater. Most major service companies dedicated their research and development into the hugely popular freshwater systems. At the same time, they recognized the future of fracturing offshore, which resulted in the development of seawater-based fluids used throughout the world today on offshore frac boats. The extension of these seawater-based fluids to onshore operations is a matter of logistics rather than requiring a leap of faith into a new technology. Acknowledging that seawater chemistry is slightly different than freshwater systems, as the industry adopts the use of seawater onshore, there will be more options available to the consumer. REGULATIONS AND INCENTIVES

Seawater is regulated by the states, and each has its own surface-water regulatory body. For example, the Texas Commission on Environmental Quality (TCEQ) is responsible for overseeing surface waters in Texas, including the seawater along its Gulf of Mexico shoreline. As such, before withdrawing any seawater, a usage permit must be obtained. Seawater is currently treated the same way as fresh. The same permits that allow water to be taken from freshwater rivers or lakes must be obtained for seawater. The permit costs several thousand dollars, and the process takes approximately 18 months. This gives ample time for the public to offer any opposition. Supply and demand, and value for money spent drive the use of technologies. The United States has large and numerous water resources. The cost of fresh water is still competitive in the big shale plays, even in the dry Southwest, but those supplies are getting tighter and more heavily regulated. In many countries, it may become government policy to restrict the use of fresh water in favor of seawater, making its use not always driven by cost. Which leads us to one final consideration for |

|

the American market—tax incentives. Certain developing technologies, such as wind-turbine generation of electricity and geothermal energy, are given incentives in the form of corporate and production tax credits. Some wind incentives last for 10 years. This lets the industry introduce, fine-tune and mature the technology in a lower tax environment. The cost of electricity from wind turbines has dropped some 40 percent during the years of refinement. Could this type of incentive scheme help spread the use of seawater for drilling and fracturing onshore in the Lower 48? Possibly.

FUTURE SEAWATER DRILLING AND FRACTURING APPLICATIONS ONSHORE Certainly oilfields within 400 miles of an ocean coastline will be top contenders for the use of seawater—the closer, the better. That is not to say that greater distances cannot be managed, but it will cost more. Using seawater for drilling and fracturing is basically a logistical challenge (using road, rail, vessels, barges and pipelines). Few fracturing experts argue against the technical merits of seawater as a base fluid for onshore operations. Indeed, some reservoirs and shale plays may benefit from contact of higher salinity fluids with the bulk volume of the rock. We believe the overall merits of using seawater far outweigh any technical challenges such as scaling tendency or a reduced rate of gel hydration. In many countries, it is not a matter of choice. Shale and unconventional resources cannot be developed using industrialized fracturing with current and future freshwater supplies, and in some cases, there are no brackish water supplies, either. It will take some work to change the industry’s habit of using fresh water. Seawater is the only massive, industrial supply in many countries, in addition to being the right environmental solution. Seawater Technologies believes that using of seawater will not only help reduce the demand on fresh water in waterstressed areas, it will also enable the continued growth of the fracturing industry outside of the U.S. as countries desiring to develop their unconventional resources free themselves from dependence on fresh water. |

CREDITS AND REFERENCES

About the Author

Brent Smith received a mechanical engineering degree from Villanova University and is the owner of Seawater Technologies. He has 33 years of oilfield experience, onshore and offshore, across Europe, Africa, North America, the Middle East, Central Asia and India. Most of his career has been related to well stimulation and completions, holding management, engineering and marketing positions. He is currently consulting, teaching and marketing his patents to the industry.

|